MEC Coatings by ThreeBond

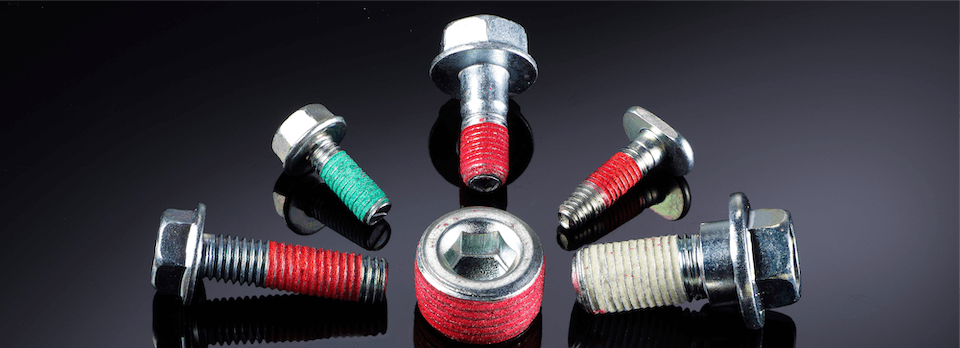

PRECOATED NUTS & BOLTS

BENEFITS OF USING MEC COATING

Eliminate errors:

line workers can be certain the adhesive is on the part, in the correct location and correct amount.

Eliminate physical locking mechanisms:

such as cotter pins and lock washers.

Reduce chance of skin irritation:

dry to the touch

Reduce component costs

and assembly time

Easy to use

with automation equipment

Environmentally friendly

Anti-tampering agent:

leaves a colored residue if the fastener is removed.

MAIN USES: SCREWS, NUTS & BOLTS THAT REQUIRE SEALING AND LOCKING

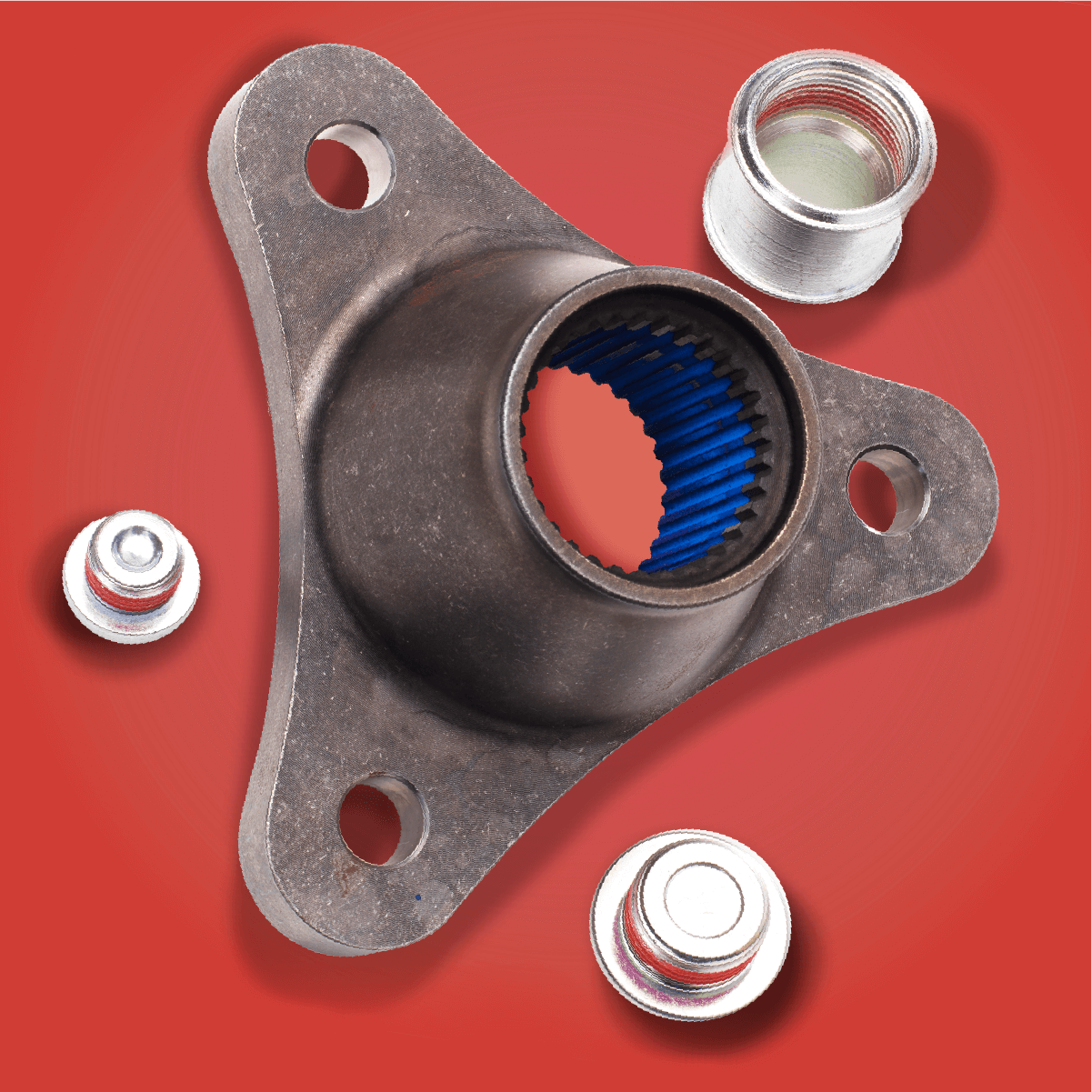

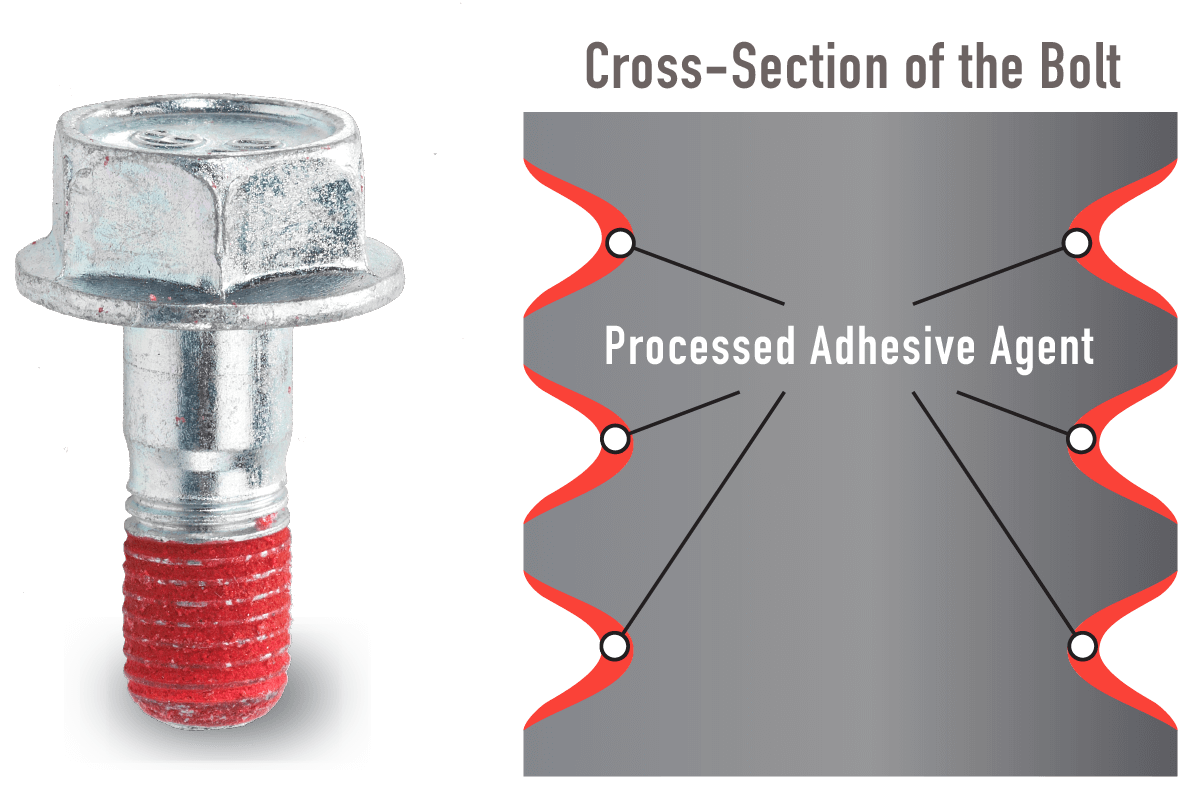

This processing technique provides fasteners with the sealing and locking function by applying micro-capsulated adhesive on the threaded parts of the bolt in a special process. When the fastener is assembled, the micro-capsule is ruptured and it adheres as a result of a polymerization reaction.

CROSS-SECTION VIEW OF A MEC-PROCESSED PART

With the surface of the threaded part processed by the micro-encapsulated high-reactive adhesive agent, the fastener is coated with the sealant and locking agent.

PRE-APPLIED MEC PRODUCTS

= Download Technical Data Sheet

← scroll to see table data →

| Classification | Part Number | Color | Applicable Dimension | Critical Temperature of Heat Resistance | Curing Speed (20-25˚C) | Main Characteristics | ||

| Locking | Sealing | Working | Final | |||||

| Low Strength | TB2458 | Green | M3 or larger | 100˚C | 170˚C | 0.5-1h | 24h | General Screws low adhesive force type easy removal |

| Medium Strength | TB2418 | Yellow | M3 or larger | 150˚C | 170˚C | 0.5-1h | 24h | General Screws low tightening resistance axial force type 2488 used for nuts |

| TB2468 | Red | M3 or larger | 100˚C | 170˚C | 0.5-1h | 24h | ||

| TB2488 | Aqua | M3 or larger | 130˚ | N/A | 0.5-1h | 24h | ||

| High Strength | TB2448 | Blue | M2~M40 | 160˚C | 170˚C | 0.5-1h | 24h | General screws high adhesive force 2448B & 2478 high heat resistance |

| TB2448B | Orange | M2~M40 | 160˚C | 170˚C | 0.5-1h | 24h | ||

| TB2478 | Aqua | M3 or larger | 130˚C | 170˚C | 0.5-1h | 24h | ||