New Series of Fuel Cell Sealing Compounds for the Automotive Industry

With a global focus on climate change, many of the topics surrounding the automotive industry center around the reduction in total emission of CO2. The development of alternative energy sources as countermeasures against the depletion of petroleum resources and controlling regulations to check air pollution are intensifying, especially in urban areas.

Because of this significant focus, fuel cell manufacturing is gaining traction as a promising new energy source. Fuel cells have proven to provide high energy efficiency and are eco-friendly. In particular, polymer electrolyte fuel cells are expected to serve as a new power source for next-generation vehicles. Because of their high current density, these cells can work at relatively low temperatures and permit the materialization of downsized cars with higher power.

What is ThreeBond’s focus on fuel cell innovation? Convinced of the great potential of the polymer electrolyte fuel cell as a new vital power source for next-generation vehicles, we have been focusing on researching and developing fuel cell sealers and compounds.

Compared to the existing internal combustion engines such as gasoline and diesel engines, this new system can provide a higher generating efficiency range between 30% and 60%. Besides, it practically emits no CO2 or other exhaust gasses, drawing attention as an environmentally-friendly, next-generation power generating system.

There are some important things to understand when it comes to the critical performance characteristics of fuel cell sealers. Since hydrogen (H2), particularly when used as fuel gas, is colorless, odorless, flammable gas with small molecular weight, it can easily leak even from a very fine clearance and is readily ignitable even with a tiny spark in a wide range of mixing. Because of these characteristics of the hydrogen (H2) as fuel gas, a sealant that can provide an almost perfect gas barrier is required between cells.

The essential characteristics required for fuel cell sealing compounds are:

Making the most of our long-experienced sealing technologies and also taking advantage of our newly developed products, we will continue to push the boundaries for our automotive manufacturing clients. Our goal is to establish even more sophisticated hydrogen gas sealing technology so that we can contribute to the development and spread of fuel cells much more actively.

Because of this significant focus, fuel cell manufacturing is gaining traction as a promising new energy source. Fuel cells have proven to provide high energy efficiency and are eco-friendly. In particular, polymer electrolyte fuel cells are expected to serve as a new power source for next-generation vehicles. Because of their high current density, these cells can work at relatively low temperatures and permit the materialization of downsized cars with higher power.

What is ThreeBond’s focus on fuel cell innovation? Convinced of the great potential of the polymer electrolyte fuel cell as a new vital power source for next-generation vehicles, we have been focusing on researching and developing fuel cell sealers and compounds.

Key Performance Characteristics of Fuel Cell Sealing Materials

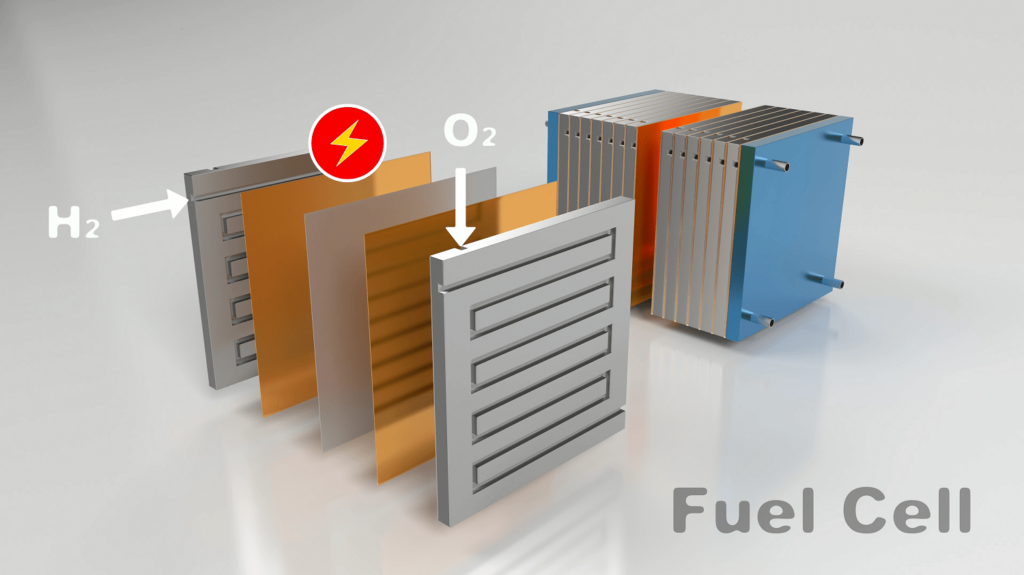

Fuel cell battery is a new system to generate electric power by means of the chemical reaction of oxygen (O2) to hydrogen (H2) that is obtained by reforming gasoline, natural gasses, or the like and is used as main fuel.Compared to the existing internal combustion engines such as gasoline and diesel engines, this new system can provide a higher generating efficiency range between 30% and 60%. Besides, it practically emits no CO2 or other exhaust gasses, drawing attention as an environmentally-friendly, next-generation power generating system.

There are some important things to understand when it comes to the critical performance characteristics of fuel cell sealers. Since hydrogen (H2), particularly when used as fuel gas, is colorless, odorless, flammable gas with small molecular weight, it can easily leak even from a very fine clearance and is readily ignitable even with a tiny spark in a wide range of mixing. Because of these characteristics of the hydrogen (H2) as fuel gas, a sealant that can provide an almost perfect gas barrier is required between cells.

The essential characteristics required for fuel cell sealing compounds are:

- High level of gas barrier capability - For sealing of hydrogen (H2) and oxygen (O2) gasses.

- Low moisture permeability - To let the polymer membrane work in saturated vapor and keep the inside of the cell wet.

- Acid resistance - To protect the inside of the cell from exposure to strong acid, which occurs when the polymer membrane functions in saturated vapor.

- Moisture resistance - Because the inside of the cell is saturated with vapor while the polymer membrane is functioning.

- Heat resistance - Because of the working conditions of the polymer membrane.

- Low ion elution - To maintain the polymer membrane’s proton-conductivity and also keep the platinum catalysts provided on the membrane active.

- Electrical insulation - To prevent short circuits between cells.

- Rubber elastic body - To absorb vibrations and impacts.

- Resistance to coolant, and methanol resistance (this in anticipation of a modified methanol or direct methanol fuel cell -DMFC-).

Making the most of our long-experienced sealing technologies and also taking advantage of our newly developed products, we will continue to push the boundaries for our automotive manufacturing clients. Our goal is to establish even more sophisticated hydrogen gas sealing technology so that we can contribute to the development and spread of fuel cells much more actively.